Quality at Lüling

Learn more about our processes and certifications.

QUALITY MANAGEMENT

From safety-relevant vehicle parts and applications in the construction industry to components in plant and mechanical engineering. Here and everywhere where LÜLING wire is processed, there is no compromise when it comes to quality: 100% reliability is required. Our total quality management is consistently implemented and documented by IATF 16949, ISO 14001 and ISO 50001.

We attach great importance to familiarising our employees with the high standards of quality and safety from the very beginning and to train them accordingly. Through continuous external training and internal training, we ensure that our team always stays up to date with the latest quality assurance.

Test procedures at Lüling

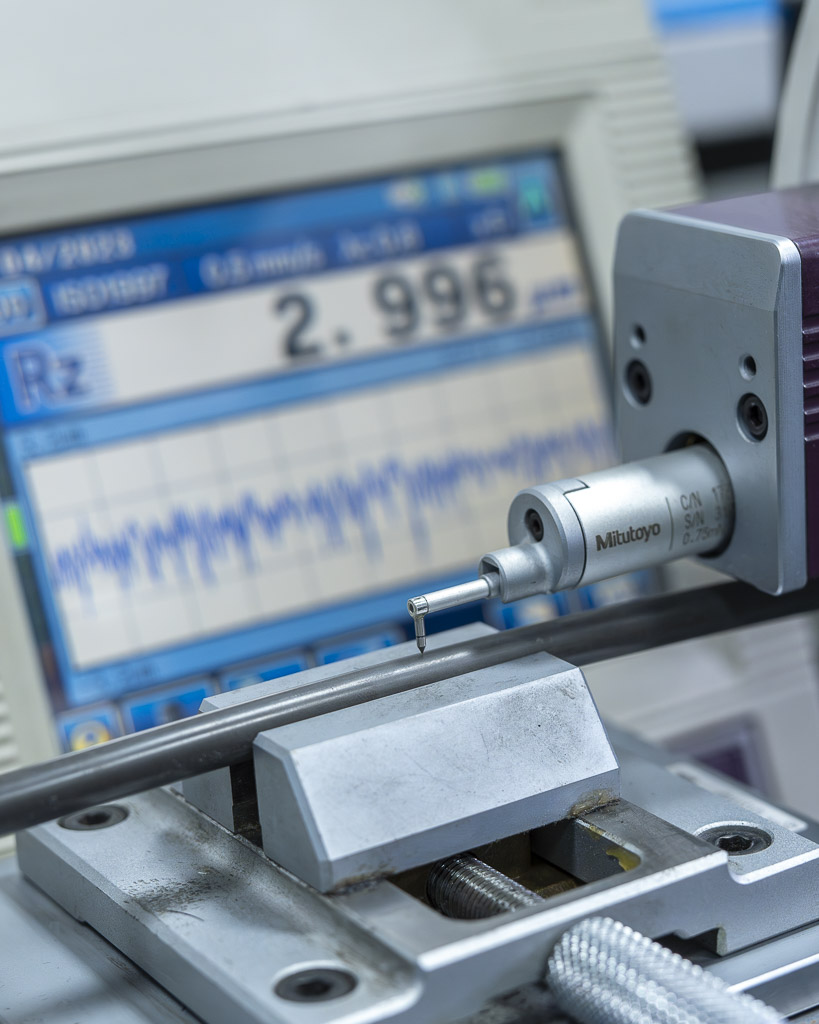

Our test laboratory specialises in testing the quality, safety, reliability and performance of our products through material tests on wires. This is the only way to ensure that our wire meets the required standards and specifications of our customers.

The main testing procedures are:

- Chemical analysis: identification and quantification of chemical components in the steel using spectral analysis.

- Mechanical testing: evaluation of the mechanical properties of wires in tensile tests.

- Metallography: Examination of the microstructure with regard to structural properties and damaged part analyses.

- In addition, wet chemical analysis is used for internal process monitoring.